premium option drum axle from China

German Drum 14T | ||||||||||||

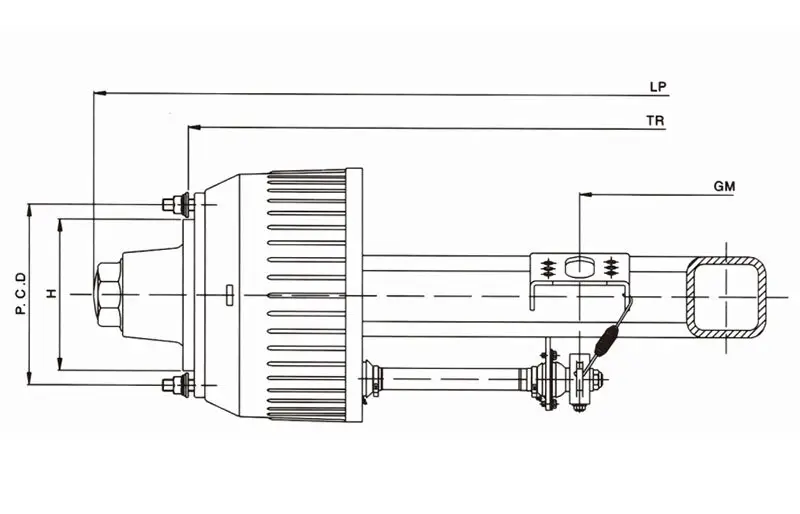

Axle Size | Max.Capacity(kgs) | Bearing | TR Track (mm) | Brake Size | AC Center Distance Of Brake Chambe (mm) | Wheel Fixing P.C.D×H | Criterion | Axle Tube (mm) | BL Brake Drum Distance(mm) | Weight (kg) | Recommended Wheel | OL Total Length (mm) |

FSA14GNS1 | 14000 | 33215/32219 | 1805 | Φ420×200 | 332 | Φ335×Φ281 | 10-M22×1.5 ISO | □150 | 1171 | 372 | ≧8.00V-20 | ≈2165 |

FSA14GNS2 | 14000 | 33215/32219 | 1820 | Φ420×200 | 347 | Φ335×Φ281 | 8-M20×1.5 JAP | □150 | 1186 | 373 | ≧8.00V-20 | ≈2178 |

FSA14GNS3 | 14000 | 33215/32219 | 1840 | Φ420×200 | 367 | Φ335×Φ281 | 10-M22×1.5 ISO | □150 | 1206 | 375 | ≧8.00V-20 | ≈2198 |

FSA14GNS4 | 14000 | 33215/32219 | 1850 | Φ420×200 | 377 | Φ335×Φ281 | 10-M22×1.5 ISO | □150 | 1216 | 376 | ≧8.00V-20 | ≈2208 |

| FSA14GNS5 | 14000 | 33215/32219 | 2040 | Φ420×200 | 551 | Φ335×Φ281 | 10-M22×1.5 ISO | □150 | 1406 | 403 | ≧8.00V-20 | ≈2422 |

◪1.The axle tube is made of girder with reinforced cross section. The material utilization rate is high, while the product is light, and its torsion resistance and bending resistance are both excellent. Besides, it is very easy to connect to the trailer suspension using our German type trailer axle.

◪2.The spindle head is forged with alloy material by a series of technical processing, including tempering, high precision machining, finishing and stress relieving. The inner races of both the big and small bearings can by pull out and push back by hands, so it is quite easy to install and maintain the product. In the field emergent operations, the advantage of our German type trailer axle is more obvious because there is no need to heat the bearings or use additional tools during the entire process.

◪3.Special lubricating grease is adopted. At the temperature from -30℃ to 150℃, the oil layer can keep great evenness and lubricating performance. Thus the bearings' service life could be extended by more than 20%.

◪4.The bearings of our German type trailer axle are purchased from famous company in China. They feature compact structure, great toughness, desirable anti-wear performance, good heat resistance, high impact resistance, high loading capacity and reliable safety.

◪5.The oil sealing mechanism of the bearings adopts a floating type oil retainer structure, which features simple installation, good sealing performance, and long service life.

◪6.The end cap of the spindle head comes in a one-piece type, making it quite simple to install and remove. In addition, the end cap in our German type trailer axle also serves as a lubricant container.

◪7. (1) The soft non-asbestos brake shoe features stable braking, high friction force, good thermostability, low braking noise, and long service life. The worn powder during the braking is harmless to human (Figure 7A).(2)The wear limit is marked both on the brake shoe and the drum brake of our German type trailer axle. So the inspection and replacement are very convenient (Figure 7B).(3) The quick-change type brake shoe comes with a hasp type return spring. So it is easy to check and change the brake shoe (Figure 7C).(4) The bayonet type mechanism is adopted for connecting the brake shoe and anchor pin, giving our German type trailer axle extra advantages like convenient installation, self-compensation, and rapid returning. The elastic C type snap ring is a wear-out part, while the body of the brake shoe is an anti-wear component which can be repeatedly used without a significant decrease in braking stability (Figure 7D). All the accessories of the braking device is in standard size, so they can be easily replaced.

◪8.Two elastic locating rings are mounted on the wheel bolt symmetrically, ensuring that the good run-out precision of the tyre assembly during the installation, as well as the thread in the wheel bolt won't be damaged due to the repeated tyre installations.

◪9.The design of our German type trailer axle is based on the international standards. Additional room is available for the installation of ABS device from different companies.

QUICK LINKS

TRAILER PARTS

contact us

Tel: +86-13356687529 / +86- 15753112927

E-mail: whw@sdfhcheqiao.com

Address: Nanwang Industrial Park, Xianggong Town, Zhangqiu City, Shandong Province, China