perfect design swing arm axle factory for aftermarket

1. swing arm axle outshine other similar products with its hydraulic trailer brakes design. Its cost-efficiency, strength, and precision have made it a hit in Frankfurt trade fair

2. Shandong Fuhua Axle Co., Ltd offers after sales technical service support to its overseas customers. The product is manufactured and processed with cutting-edge computer numeric control technology

3. The product is resilient to vibration and impact. It has been manufactured by casting, milling, or forging to be more resilient. Processed by die forging and thermal treatment, the product boasts high strength and excellent stability

4. Fatigue resistance is one of the most important mechanical characteristics of this product because it is generally used under cyclic loading conditions. The product delivers satisfying performance in harsh conditions, be it in freezing Siberia or scorching Mid-East countries

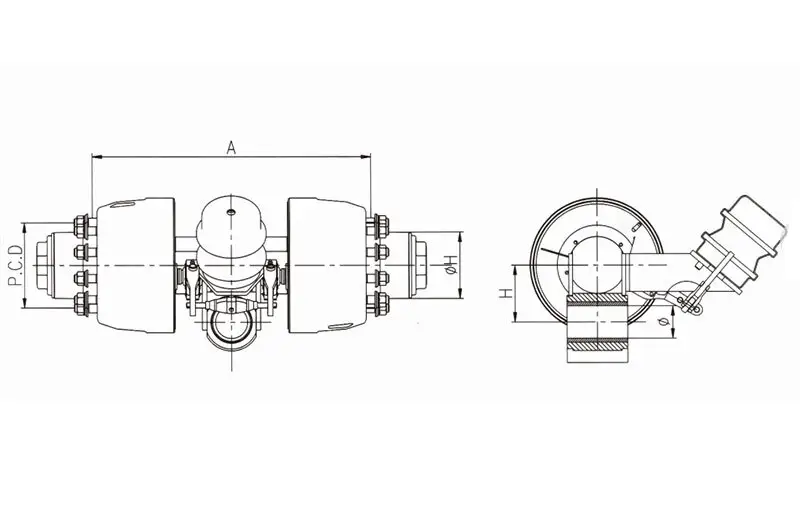

Hydraulic swing arm axle serie | ||||||||||

Axle Size | Max.Capacity(kgs) | Bearing | A Track (mm) | Brake Size | Dia of bore (mm) | Central Height (mm) | Wheel Fixing P.C.D×H | Criterion | Recommended Wheel | Tyre |

FSA15HNR1 | 15000 | HM518445/10 | 750 | Φ311×130 | Φ90 | 80 | Φ225×Φ176 | 10-M22×1.5 ISO | 7.50V-15 | 10.00V-15 |

FSA16HNR2 | 16000 | HM518445/10 | 815 | Φ310×190 | Φ100 | 160 | Φ225×Φ176 | 10-M22×1.5 ISO | ≧6.50V-15 | 8.25-15 |

FSA16HWR1 | 16000 | HM518445/10 | 940 | Φ420×180 | Φ100 | 160 | Φ335×Φ281 | 10-M22×1.5 ISO | 7.50V-20 | 10.00-20 |

FSA20HNR1 | 20000 | HM518445/10 | 965 | Φ420×220 | Φ100 | 160 | Φ225×Φ176 | 10-M22×1.5 ISO | 8.00V-20 | 11.00-20 |

| FSA32HWR1 | 32000 | HM518445/10 | 1200 | Φ420×180 | Φ120 | 160 | Φ225×Φ176 | 10-M22×1.5 ISO | 8.50V-20 | 12.00-20 |

| FSA40HWR2 | 40000 | HM518445/10 | 1200 | Φ420×220 | Φ165 | 160 | Φ225×Φ176 | 10-M22×1.5 ISO | 8.50V-20 | 12.00-20 |

◪1.The axle body and the axle head of our American type trailer axle are manufactured as one piece with high quality low alloy seamless steel pipe using thermal extrusion forming technique (Figure 1A). The metal fiber in the axle body keeps its original streamline (Figure 1B). Thus the axle body can get high strength and loading capacity, as well as long service life.

◪2. The American type trailer axle, after being tempered, has an ideal grain size (Grade 7 or Grade 8). The bearing position is treated by medium-frequency hardening technique, making it highly fatigue resistant.

◪3.. Due to the adoption of advanced one-piece thermal extrusion forming technique, our axle is lighter than other products with the same loading capacity. The dynamic factor this trailer accessory is higher than 2.5, making this axle more cost effective.

◪4.The eco-friendly non-asbestos brake shoe is adopted for our American type trailer axle. Due to our high precision processing, the braking system is more stable and efficient, while the service life is also longer.

◪5. The camshaft comes with special sealing element, ensuring no lubricating grease will enter the drum brake. Thus the driving safety can be enhanced.

◪6.The latest sealing wheel hub cover comes with an O-type seal ring whose sealing performance is much better.

◪7.We have adopted a designing solution for our American type trailer axle in accordance with the international standards, so all the accessories are interchangeable. The usage is mature convenient and economical.

◪8.Various kinds and models of axles are available. Custom products can also be provided as per your demands.

Company Features

1. Shandong Fuhua Axle Co., Ltd is a renowned manufacturer with expertise in developing, designing, and manufacturing hydraulic trailer brakes . We have received many compliments over the years.

2. Our swing arm axle is easily operated and need no additional tools.

3. Shandong Fuhua Axle Co., Ltd is dedicated to 'Good Faith', 'Better Services' and 'Best Attitude'. Call!

QUICK LINKS

TRAILER PARTS

contact us

Tel: +86-13356687529 / +86- 15753112927

E-mail: whw@sdfhcheqiao.com

Address: Nanwang Industrial Park, Xianggong Town, Zhangqiu City, Shandong Province, China