high quality bogie truck brand

Our bogie suspension, as a trailer suspension system, comes in various types, including high frame type, low frame type, cantilever type, and so on. It features simple, sturdy, and durable structure, and is in normal height. The low frame type suspension is suitable for normal cars, as well as high clearance vehicles due to the great stability during the braking. Besides, our technical service team can also help you choose the right model. If you need special products, our technical team will design the proper bogie suspension according to your requirements. Our annual production for suspension is 18,000 sets, which means short lead time. In the vehicle suspension industry, we have accumulated more than 10 years of experience. A complete range of production machines and testing equipment have been introduced to ensure the excellent and consistent quality of our bogie suspension.

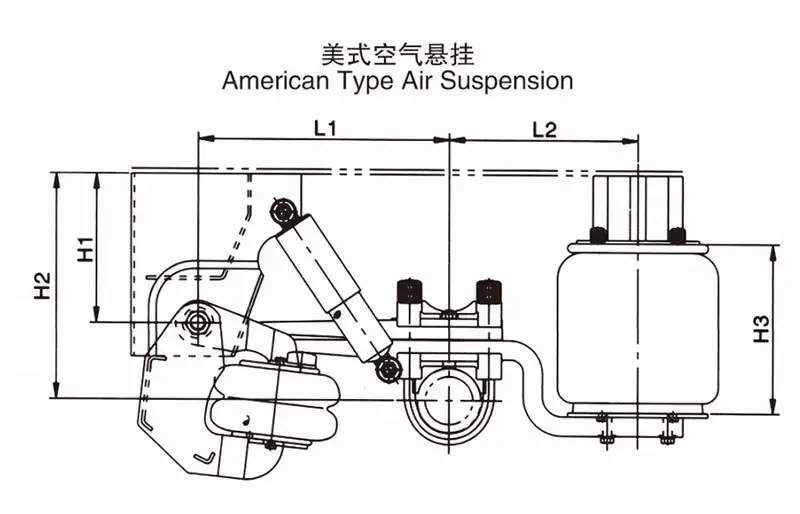

Air Suspension | ||||||||||

Model | Axle Lift | Rated Load(kg) | Axle Beam(mm) | Leaf Spring(mm) | Air Bag Spec | L1(mm) | L2(mm) | H1(mm) | H2(mm) | H3(mm) |

FSAS11ANR1 | No | 11000 | Φ127 | 2-100×38 | 350 | 500 | 380 | 296 | 442 | 335 |

FSAS11ANR2 | No | 11000 | Φ127 | 2-100×38 | 350 | 500 | 360 | 276 | 210 | 257 |

FSAS11ANR3 | Yes | 11000 | Φ127 | 2-100×38 | 350/260 | 500 | 380 | 251 | 400 | 407 |

FSAS11ANS1 | No | 11000 | □150 | 2-100×38 | 350 | 500 | 380 | 231 | 400 | 413 |

| FSAS11ANS2 | Yes | 11000 | □150 | 2-100×38 | 350/260 | 500 | 380 | 231 | 400 | 413 |

| FSAS9GNR1 | No | 9000 | Φ127 | 1-100×50 | 350 | 500 | 380 | 268 | 210 | 318 |

| FSAS9GNR2 | No | 9000 | Φ127 | 1-100×50 | 350 | 500 | 380 | 268 | 426 | 318 |

| FSAS9GNR3 | Yes | 9000 | Φ127 | 1-100×50 | 350/260 | 500 | 380 | 268 | 210 | 318 |

| FSAS9GNR4 | Yes | 9000 | Φ127 | 1-100×50 | 350/260 | 500 | 380 | 268 | 426 | 318 |

| FSAS12GNR1 | No | 12000 | Φ127 | 2-100×35 | 350 | 500 | 380 | 268 | 422 | 423 |

| FSAS12GNR2 | Yes | 12000 | Φ127 | 2-100×35 | 350/260 | 500 | 380 | 268 | 422 | 423 |

| FSAS12GNS1 | No | 12000 | □150 | 2-100×35 | 350 | 500 | 380 | 268 | 445 | 423 |

| FSAS12GNS2 | Yes | 12000 | □150 | 2-100×35 | 350/260 | 500 | 380 | 268 | 445 | 423 |

◪ 1.Central axle pedestal

The central axle is made of premium low alloy seamless steel pipe, and processed by tempering and various high precision processing techniques. Thus the axle’s strength is greatly enhanced. The panel is made of high-strength low alloy steel plate by punch forming technique, so it is strong and durable. Other supporting accessories are all welded by high-strength low alloy plate. The central axle pedestal comes with stiffening girder in it, making the whole structure of our bogie suspension highly resistant to the twisting force and bending force.

◪ 2. Central bearing pedestal

The anti-wear sliding bearing (with copper bush) embedded design is adopted. Thus the central axle and the bearing are more stable and have longer service life.

◪ 3.Leaf spring pedestal

The nodular cast iron is used for the leaf spring pedestal of our bogie suspension to make it more anti-wear and impact resistant. The coupler between leaf spring pedestal and leaf spring assembly comes in rubber inner-bushing and separating design, which can effectively lower the abrasion coefficient between the leaf spring and spring pedestal, and make the service life of the two components longer.

◪ 4. Leaf spring

The leaf spring is made of high-strength alloy leaf spring, and processed by advanced European processing techniques. The spring of our bogie suspension features high strength, great durability and is highly interchangeable.

◪ 5. Simple structure

Our bogie suspension has a simple and compact structure. It mainly comprise of five components, including Central axle pedestal, central bearing pedestal assembly, leaf spring pedestal assembly, leaf spring pedestal, and axel. It is mounted onto the suspension by bolted connection, making the later maintenance and repairing quite simple and convenient.

◪ 6.The bogie suspension has low requirements for the road surface because of its great adaptability.

QUICK LINKS

TRAILER PARTS

contact us

Tel: +86-13356687529 / +86- 15753112927

E-mail: whw@sdfhcheqiao.com

Address: Nanwang Industrial Park, Xianggong Town, Zhangqiu City, Shandong Province, China